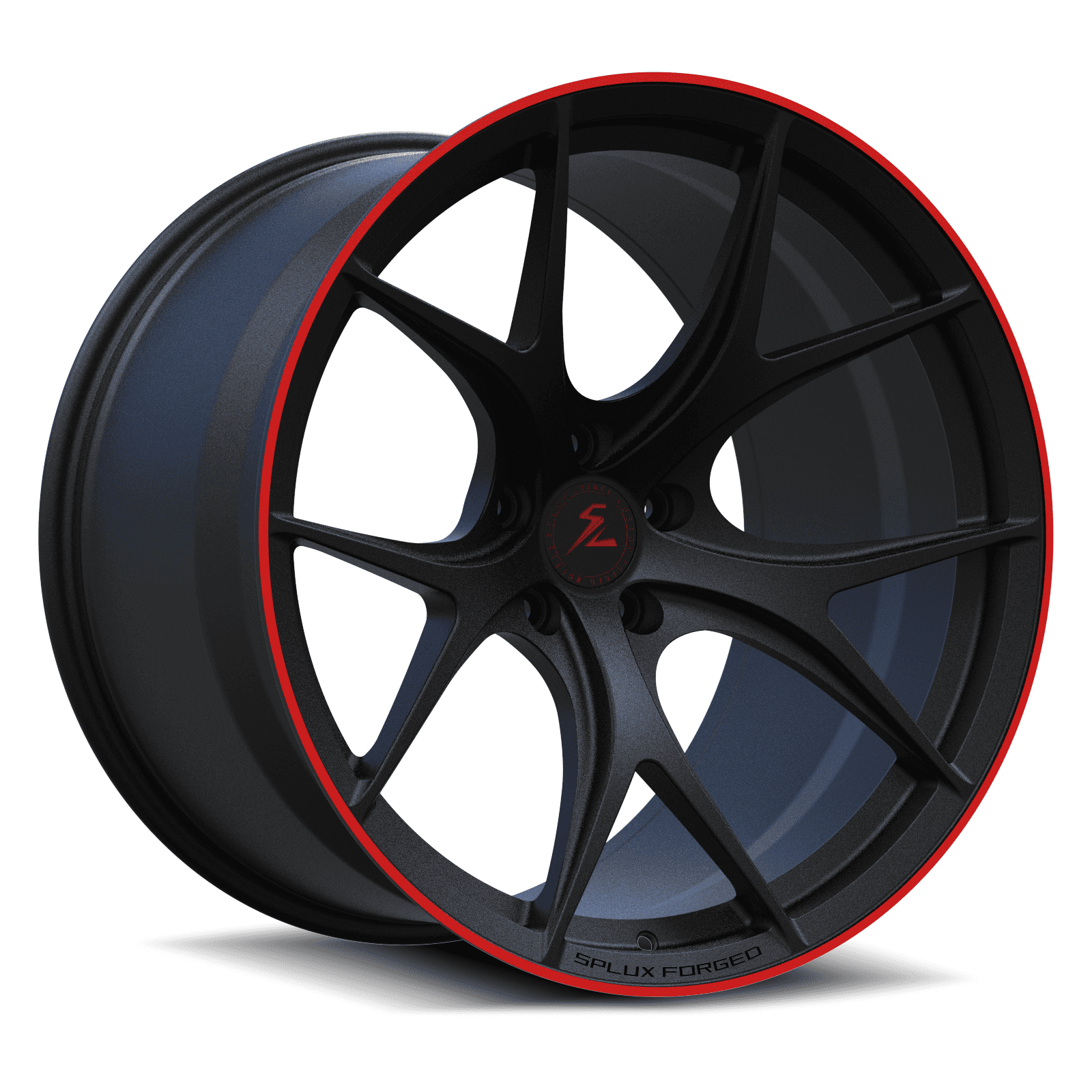

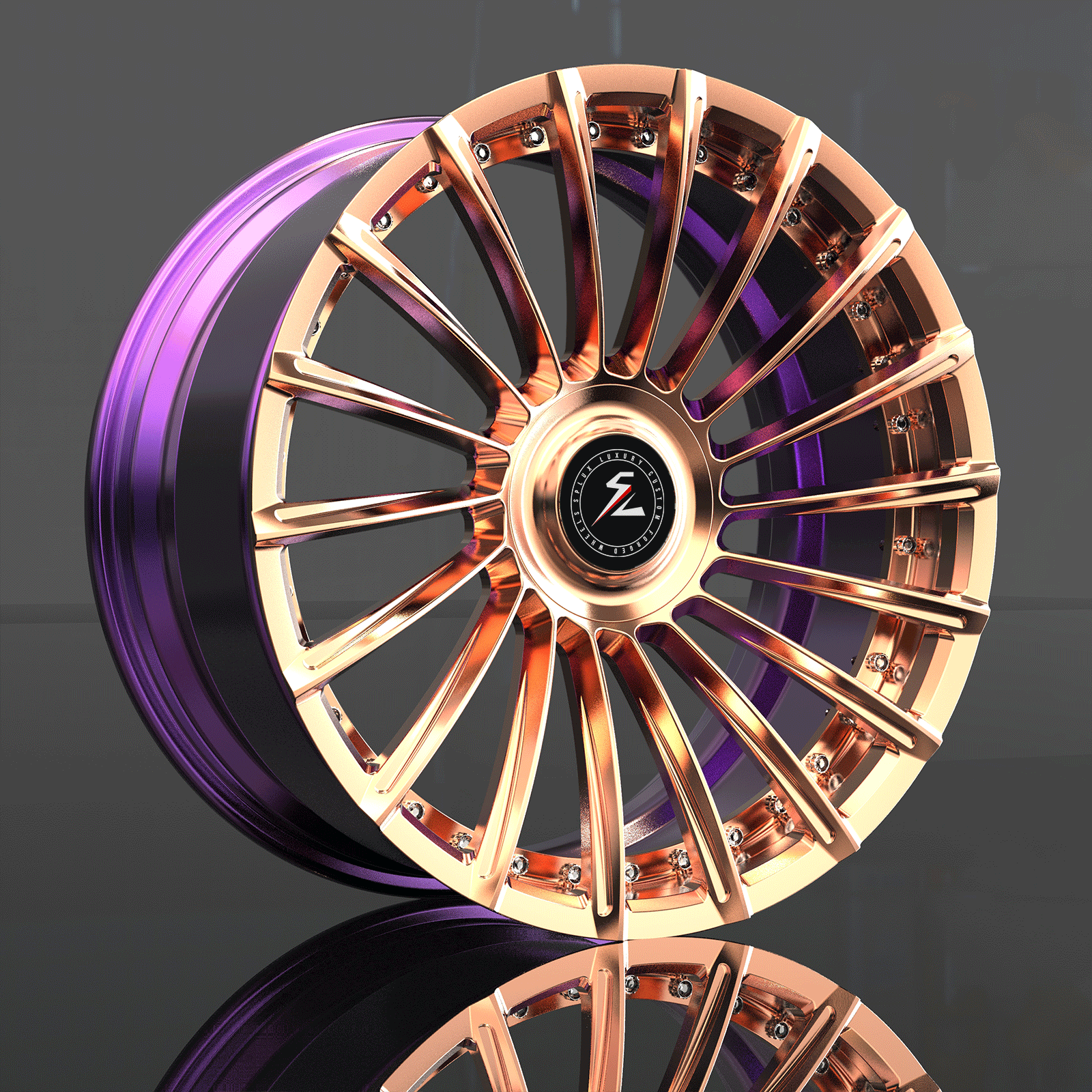

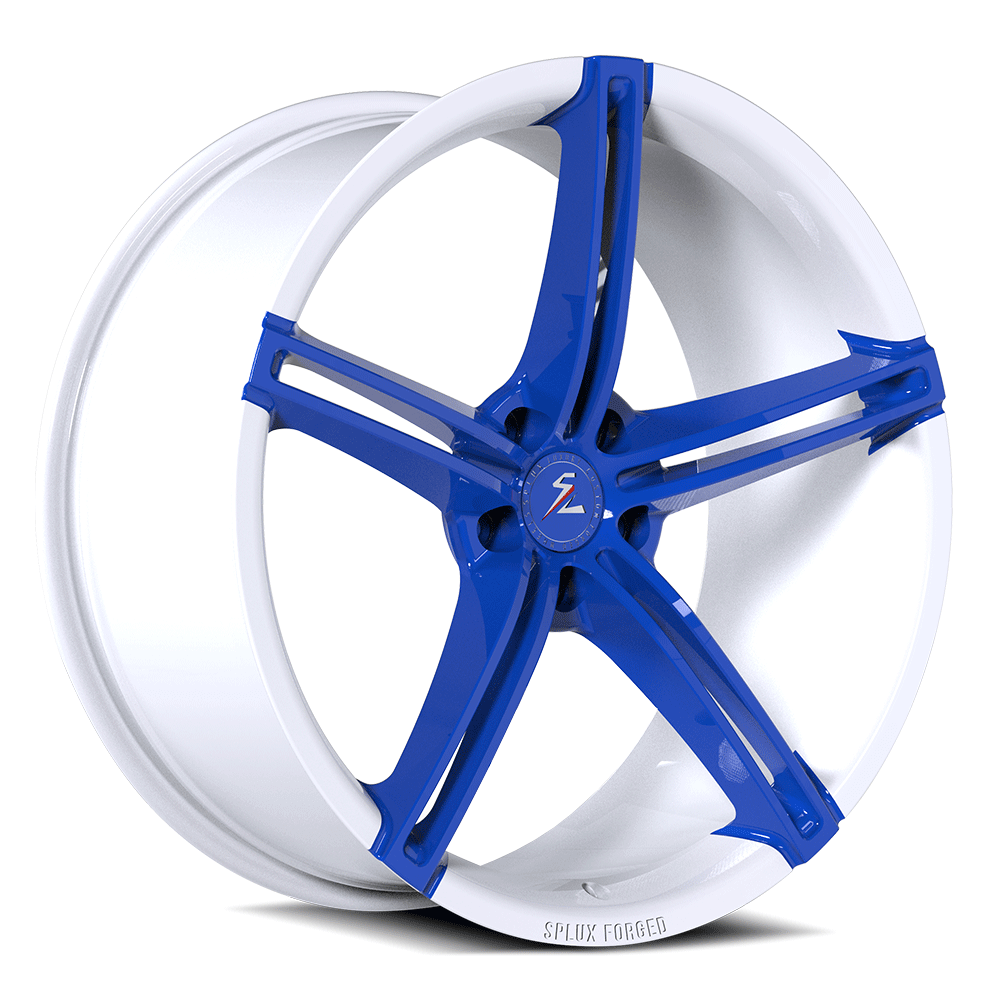

Why Choose SPLUX Forged Wheels? The Essential Guide: Forged vs. Flow Form vs. Cast

by Splux Wheels on Oct 11, 2025

In the high-stakes world of automotive performance, every component you add or replace is a profound declaration of intent. No part is more critical—or more misunderstood—than the wheel. It's the essential connection between your horsepower and the road, a rotating mass that dictates everything from your acceleration and braking to your handling and suspension longevity.

For the serious enthusiast or high-end builder, the choice quickly boils down to a fundamental engineering question: What manufacturing method best serves my pursuit of performance and safety?

At SPLUX Wheels, we engineer our products for those who demand the absolute maximum in strength, precision, and weight reduction. We believe in the uncompromising nature of fully forged construction.

[Don't wait to upgrade. Explore the SPLUX Forged Wheels Collection Now]

To understand why this choice is non-negotiable for superior performance, one must first look beyond the finish and into the very grain of the metal.

1. The Manufacturing Divide: An Unbreakable Law of Physics

The differences among cast, flow-formed, and fully forged wheels are not simply a matter of price; they are a direct result of the manufacturing pressure principle. The amount of mechanical force applied to the raw aluminum

The Foundation: Cast Wheels

- The Process: Molten aluminum is poured into a mold. Whether by simple gravity or low-pressure injection, this is the path of least resistance.

- The Result: Since the metal cools without extreme mechanical force, the internal grain structure remains non-aligned, less dense, and often porous. To be safe for the road, the wheel must use significantly more material.

- The Trade-Off: Lowest Cost / Highest Weight. Adequate for everyday driving, but the first to compromise when subjected to high lateral loads, aggressive tires, or severe road impacts.

The Middle Ground: Flow Formed Wheels

- The Process: This is a hybrid approach. The wheel face is cast (like a standard cast wheel), but the barrel is then intensely heated and spun while powerful rollers compress and stretch the metal.

- The Result: The grain structure is refined and aligned only in the high-stress barrel area, significantly improving strength and allowing for a thinner, lighter barrel.

- The Trade-Off: Moderate Cost / Good Weight Reduction. An excellent bridge for a dedicated street car or entry-level track use, offering a superior strength-to-weight ratio than casting without the full cost of forging.

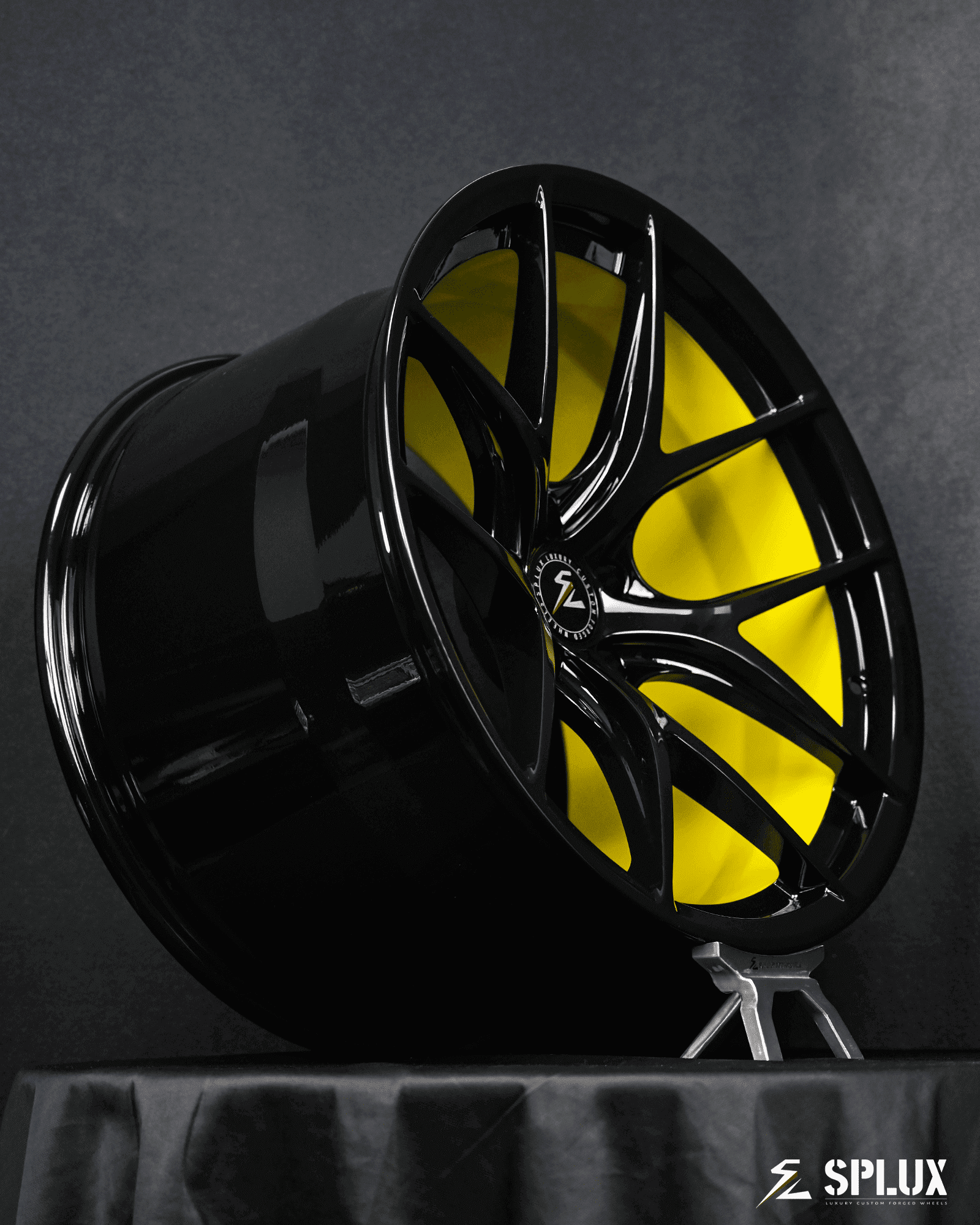

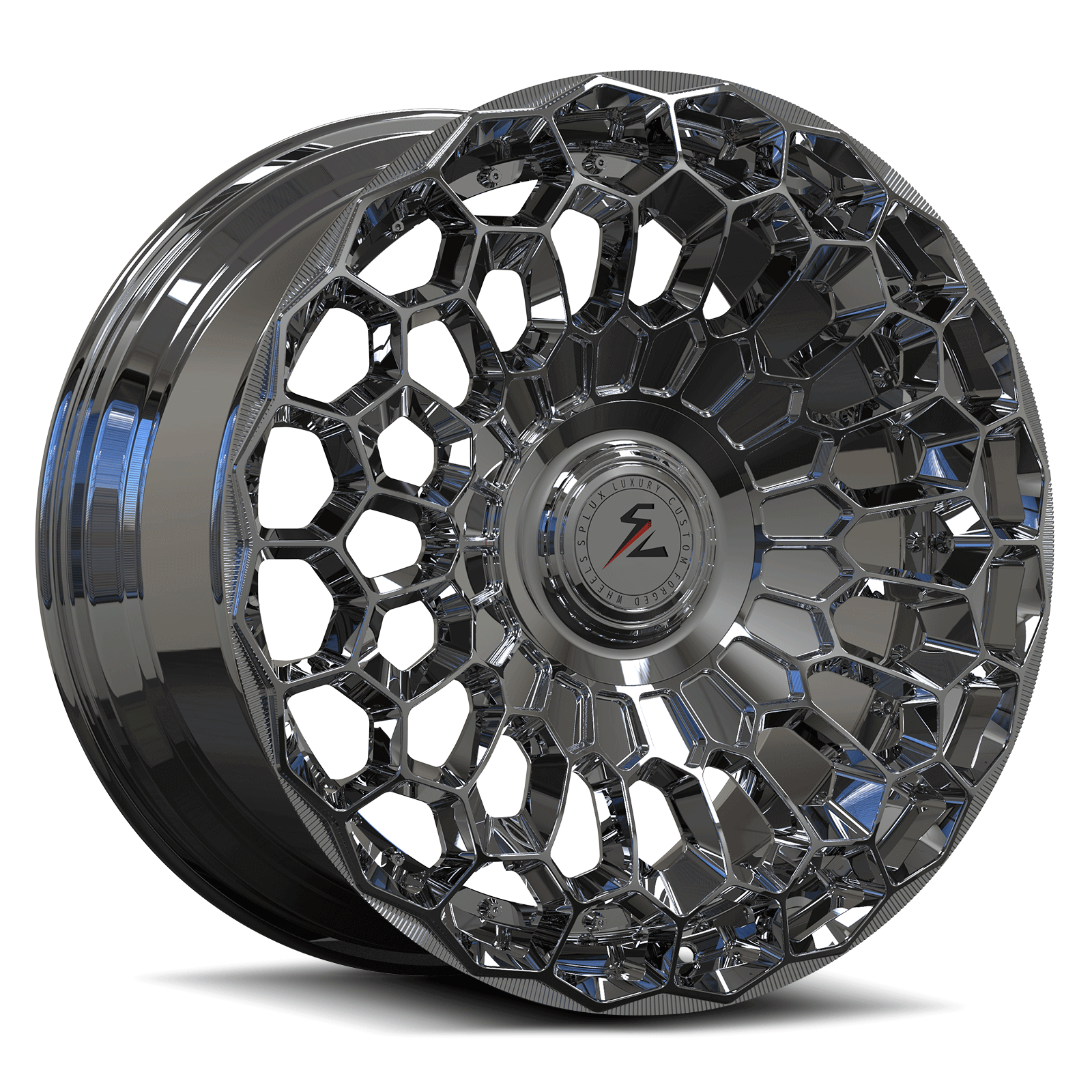

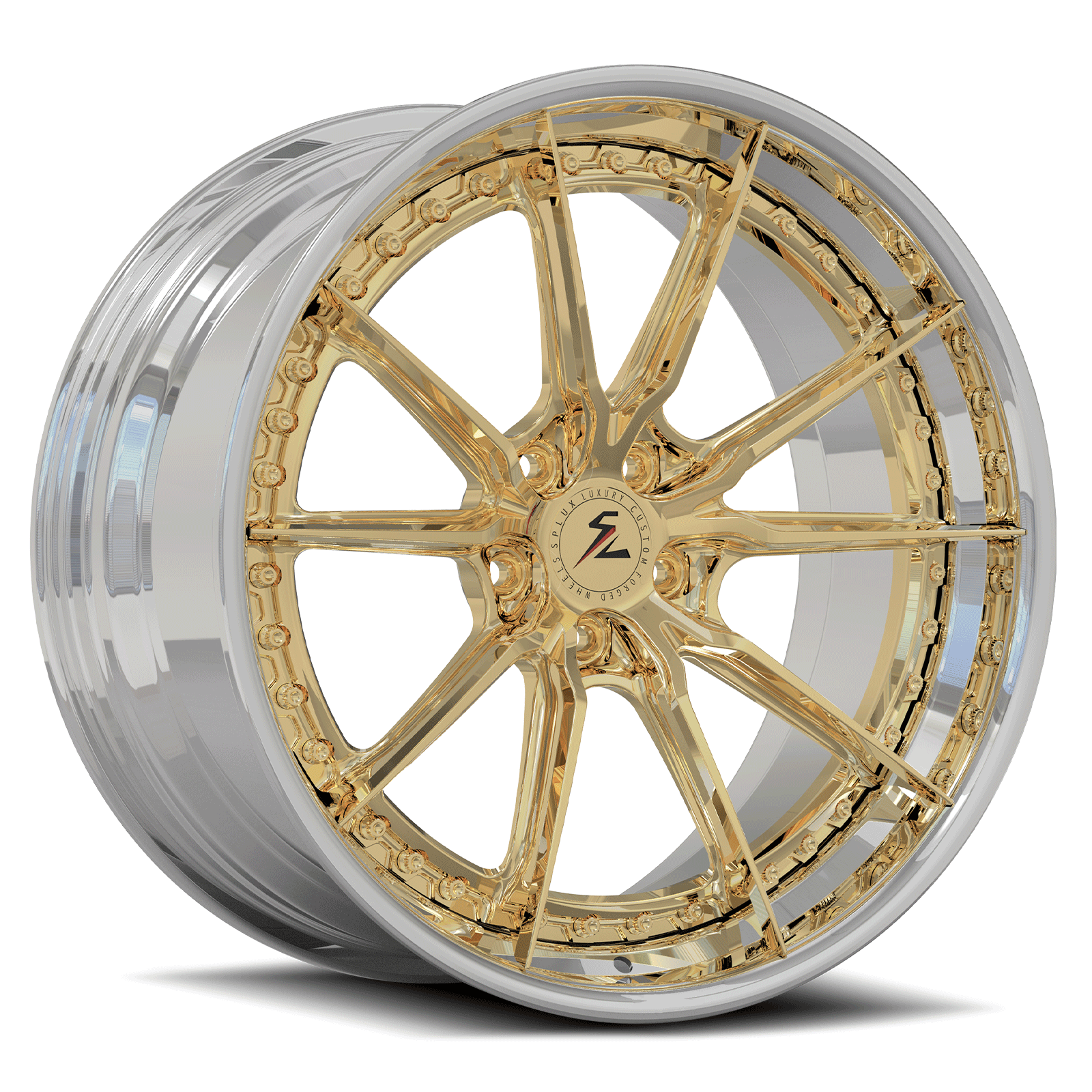

The Standard Bearer: Fully Forged Wheels

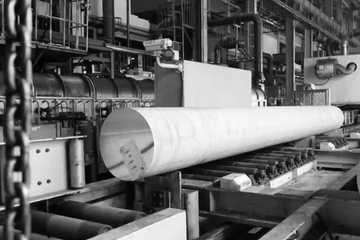

- The Process: The wheel does not start as a liquid. It begins as a solid, cylindrical block, or billet, of aerospace-grade aluminum. This billet is subjected to extreme heat and crushing, multi-directional force—often 6,000 to 12,000 tons of pressure.

- The Result: This immense force physically compacts and aligns the metal’s grain structure into a single, continuous, homogeneous form. This eliminates internal voids and maximizes the material’s inherent strength and fatigue resistance across the entire wheel. The final shape is then meticulously carved out on a high-precision CNC machine.

- The Trade-Off: Highest Strength / Lowest Weight. This is the uncompromising statement of maximum performance.

2. The SPLUX Advantage: Strength You Can Trust

At SPLUX, we don't just use the forging process; we utilize the highest-grade raw material to ensure your wheel is an ultimate expression of reliability and performance.

Pushing the Limit: Our 12,000-Ton Forging Press

The power applied during forging is the direct determinant of the wheel's quality. While many forging manufacturers use a standard 6,000-ton press, SPLUX utilizes a 12,000-ton forging press. This is a critical difference:

| Feature | SPLUX 12,000-Ton Press (Premium Performance) | Standard 6,000-Ton Press (Standard Capability) |

| Forging Pressure | Extremely high pressure enables ultra-dense grain structure with superior stability. | Moderate pressure, sufficient for basic forging tasks. |

| Structural Strength | Outstanding mechanical strength and fatigue resistance; ideal for high-stress applications. | Adequate strength for general use; not ideal for extreme performance. |

| Design Capability | Supports deep concavity, large diameters, and intricate profiles. | Limited ability with complex designs or aggressive dimensions. |

Aerospace-Grade 6061-T6 Aluminum

Every SPLUX forged wheel starts with a billet of aerospace-grade 6061-T6 aluminum. This specific alloy is the industry standard for high-stress applications, used in everything from aircraft components to structural elements in high-performance racing.

By combining the material's innate toughness with the grain-refining power of our massive forging press, we achieve a wheel that is:

- Dramatically Stronger than a standard cast wheel.

- Significantly More Ductile (less brittle), allowing it to bend rather than shatter upon severe impact.

- Naturally Lighter because the superior strength allows us to CNC machine away more material without sacrificing integrity.

Performance Payback: Why Weight Reduction is Everything

The primary benefit of a forged wheel is its dramatic reduction in unsprung weight—the mass not supported by your suspension.

When you invest in SPLUX forged wheels, you immediately unlock a cascade of performance benefits that cannot be achieved by simply increasing horsepower:

| Performance Metric | How Forged Wheels Improve It |

| Handling & Grip | Lighter wheels allow the suspension to react faster and more accurately to road imperfections, keeping the tire in contact with the ground for maximum grip and cornering stability. |

| Acceleration | Less rotational mass requires less energy to spin up, translating directly to a quicker 0-60 mph time and a sharper feel off the line. |

| Braking | Lighter rotating mass carries less kinetic energy, reducing the load on your brakes and improving stopping distances. |

| Suspension Life | Reduced mass lowers the stress on shock absorbers, springs, and bushings, enhancing comfort and component longevity. |

The Ultimate Commitment: Lifetime Structure Warranty

We stand behind the brutal precision of our forging process. Every set of SPLUX wheels comes with a Lifetime Structure Warranty. This is our commitment to the structural integrity and long-term safety of your investment, providing you with absolute peace of mind regardless of how aggressively you drive.

Ready to upgrade to uncompromising performance? [Explore the SPLUX Forged Wheels Collection]

Your Next Decision is a Declaration

Choosing a wheel is a philosophical decision. It's a choice between economy, compromise, or ultimate structural integrity.

- Do you require dependable utility (Cast)?

- Are you looking for a mass-market, efficient choice (Flow Form)?

- Or do you demand the absolute pinnacle of engineering, prioritizing strength and weight reduction, while requiring the precise, custom fit that only forging can deliver?

If your answer is the latter, your vehicle is ready for the uncompromising performance and safety of SPLUX Forged Wheels.

Ready to start your build?

View the SPLUX Forged Wheels Collection and Start Your Build Today